1.1 Compact structure, light weight, safe and reliable.

1.2 High universality, interchangeability and lifting capacity.

1.3 Convenient ,easy maintenance and operation ,stable lifting.

1.4 It is the most widely used and popular light lifting equipment.

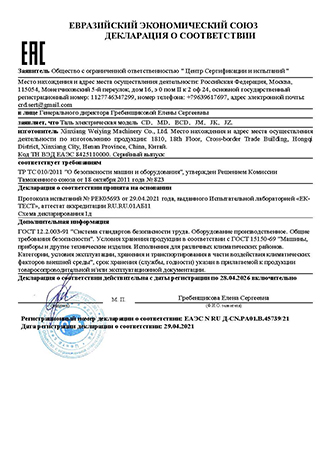

Our company mainly manufactures electric hoists with lifting capacity of 0.25~63t, lifting height of1~100m, working class of M3~M4, also can design and manufacture according to requirements.

It is applicable in the temperature of -25℃~+40℃, Humidity≤85%, Altitude below 1000m, Power is

3-phase 380v 50HZ(also can be customized according to customer’s requirements)

Capacity : from 0.5 T to 32t

Lift height: 3m to 60 m

Working duty: A3, A4,A5

Speed:single speed

Voltage:380/220/400/440V 50/60HZ 3phase CE, TUV, GOST certificate, Top quality

|

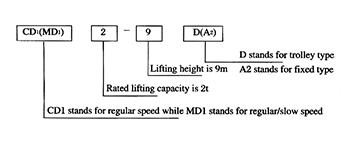

Classification

Single speed CD1, Double speed Md1,Explosion-proof, Metallurgic,Low headroom hoists etc. |

|

|

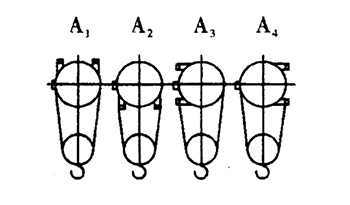

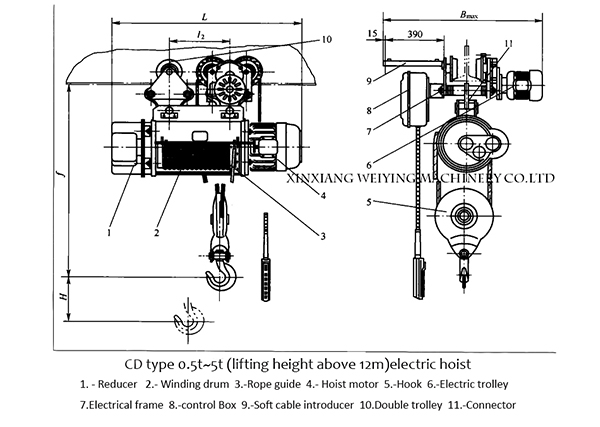

Structure Layout

Stationary type and operation typeboth included. As shown on the right: A1、A2、A3、A4 separately fixed on the up, down, left and right side. A2 always used on the trolleyof double beam crane with hoist. It is usually operation type without special explanation, traveling along with beams. |

|

|

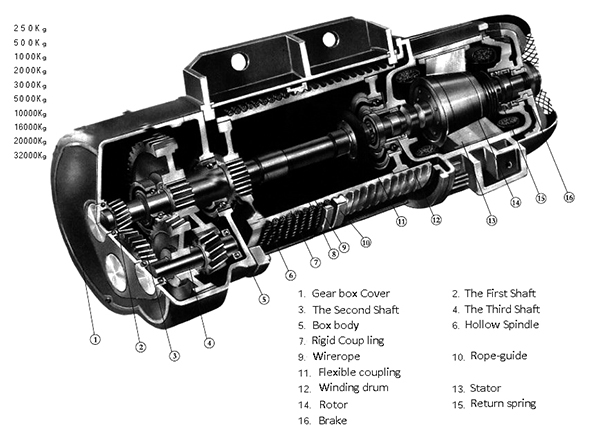

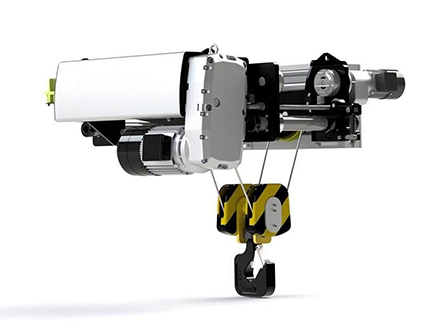

Lifting Motor

1.Tapered rotor three-phase asynchronous braking motors 2.High starting torque, effective braking, compact structure 3.Stable operation, small volume and light weight 4.Safety in use, convenient maintain 5.B or F class insulation, IP44, IP54 protection |

|

|

Travelling Motor

1.Use tapered rotor of three-phase asynchronous braking motors 2.Stable starting,safe braking, can be used with reducer 3.B grade or F grade of insulation,closed structure,motor protection grade is IP44 or IP54. 4.Brand: Nanjing special motor |

|

|

Reducer

1.Three-level dead axle helical gear rotating body, long service life 2.Gear and the axle made by alloy steel after heat treatment, high intensity 3.Box and cover made from superior cast iron, fully covered 4.Great speed ratio, high accuracy 5.Compact structure, silent operation, high efficiency |

|

|

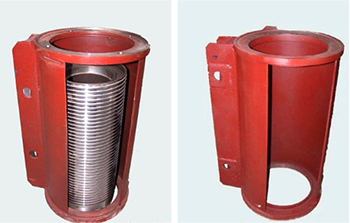

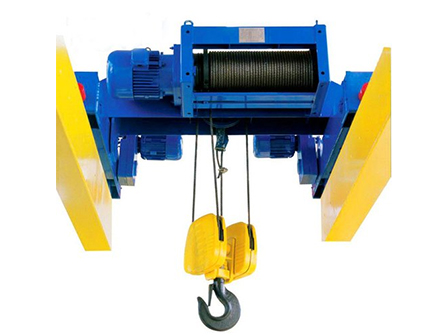

Rope Drum

Made of cast iron or seamless steel tube, light weight, transmit the dynamic force by splines. Coil casing made from superior cast iron, high intensity. The drum is the central part of the hoist. It connect with travelling mechanism above through balance beam,with reducer and motor both sides, and with wire rope and hook below. Installed limited guide bar equipment to the up front of the outer cover. |

|

|

Travelling Mechanism

The wheel tread is straight when used with box type girder or H beam. The wheel tread is circular arc when used with I-beam. Its travelling speed is 20m/min, but 30m/min is possible; if 1~5t capacity with 12m or higher lilfting height, a driven trolley is necessary. |

|

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.