1. Low noise, commodious cabin and good view .

2. Safe and reliable traveling .

3. Smooth starting and stopping ,Saves electricity specifications .

4. Excellent exchange ability for parts ,Convenient maintenance

5. Overload limiter , Limit switch (lifting and traveling) , Interlock protection device , Buffer , Anti Collision device and so on .

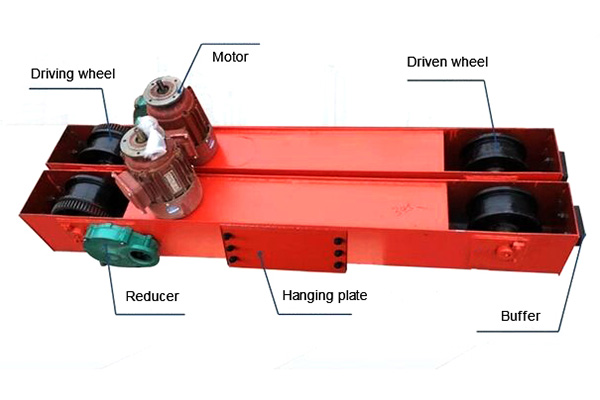

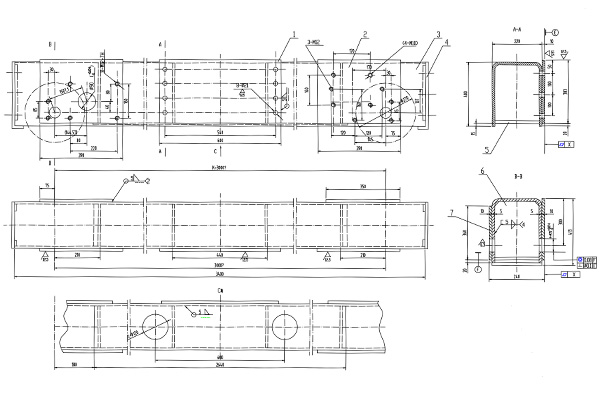

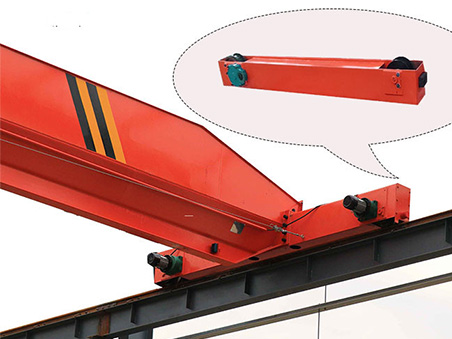

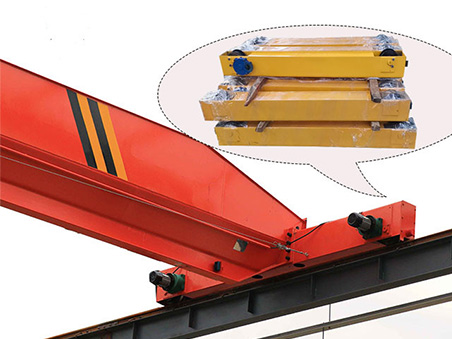

1.Bridge Crane End Beam use rectangular tube manufacturing module, buffer motor drive, match with forged wheels, using numerical control lathe boring and milling of various Customized machine

2.A set of end beams consists of 2 frames, 4 wheels (2 active, 2 driven), 2 motors, 2 reducers, 4 bumpers (anti-collision device), and 2 hanging plates (connecting plate)

3.simple structure, light weight, space utilization high, low noise and maintenance

| End carriage mode | Application of crane model | Rectanglar steel tube | Wheel size | Motor power |

| L125-15 | 1t-7.5m | 150*150*6 | W125*60 | 0.3KW*2 |

| L125-20 | 1t-11.5m | |||

| L125-25 | 1t-16.5m | |||

| L160-15 | 2t/3t-7.5m | 150*200*8 | W160*70 | 0.4KW*2 |

| L160-20 | 2t/3t-11.5m | |||

| L160-25 | 2t/3t-16.5m | |||

| L200-20 | 5t-11.5m | 150*250*8 | W200*70 | 0.4KW*2 0.75KW*2 |

| L200-25 | 5t-16.5m | |||

| L200-30 | 5t-22.5m |

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.