1. Crane operators must strictly adhere to operating procedures. Before each use, conduct an empty run and inspect the rotation, movement, elevation, and limit mechanisms. If any anomalies are detected, the crane should be stopped for inspection and repairs before being put into operation.

2. Overloading is strictly prohibited. When lifting loads close to the rated capacity, use weight data or estimation to ensure safety.

3. Buffer devices or plates at both ends of the cantilever I-beam track are for non-limiting purposes only. They should not be used as a normal stopping method during routine operations and should not be frequently impacted.

4. Ropes used to secure heavy objects must possess sufficient strength and be securely fastened. Ropes should be properly guided around sharp corners of the load, and ropes attached to the lifting hook must be positioned centrally to prevent slipping.

5. Lifting loads at an angle is not allowed. It’s prohibited to drag or forcibly lift buried objects using the lifting hook, and the crane’s swing arm should not be used for dragging or impact tasks.

6. No personnel are allowed above the lifted load, and pedestrians are prohibited from standing below the lifted load.

7. After completing work or during breaks, heavy loads should not be suspended in the air for extended periods to prevent permanent deformation of the structure.

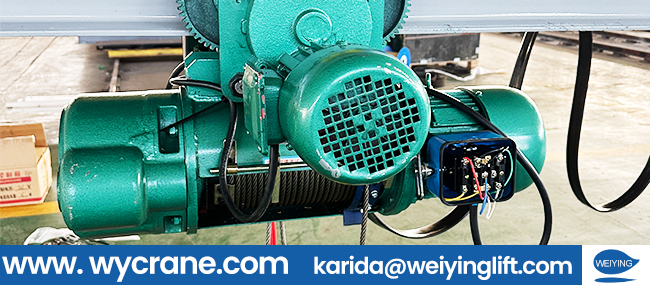

8. The limit switch on the electric hoist is a safety device to prevent accidents caused by the hook ascending or descending beyond the limit positions. It should not be used frequently to control travel and must not be removed.

9. Depending on the environment, regularly remove accumulated debris from the rotating cantilever and the flanges of the cantilever I-beam (or the walking track). If paint is peeling, touch up or repaint as needed based on the specific situation.