Simple structure, installation, use, and maintenance are all convenient.

Parts standardization, the generalization and seriation.

Good in usability and produce conveniently

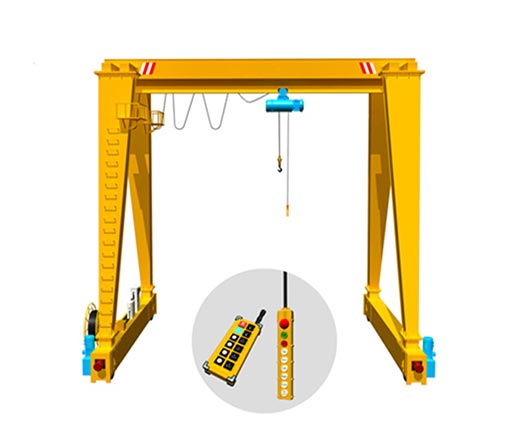

Our company produce MH type single girder gantry crane series with electric hoist ,mainly with the lifting capacity of 3-16t, span 12-30m, the lifting height of 12-30m, and the light (A3/A4) working duty, also can design and manufacture non-standard series hoist according to your demands.

Load capacity: up to 32 tons

Span:up to 30m

Long-travel speed : up to 30m/min

Cross-travel speed: up to 20m/min

Lifting speed: up to 8m/min

Non-standard specifications on request Gantry Frame

Mainly composed of main girder, ground beam, landing legs, outrigger, ladders, platforms, driver's room, etc.

|

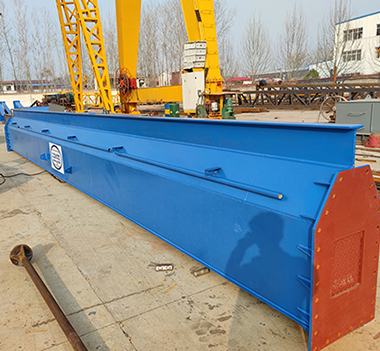

Main girder

1.Main bearing structure, traveling rail of electric hoist. 2.Material Q235B or Q345B ( similar as Fe37 or Fe52). 3.U-type groove, inclined plate, rib plate made by cold bending suppress steel plate weld solid web girder with I beam, or truss girder welded by steel plate group 4.Arched main beam according to request, the arch degree F should be (1/1000~1.4/1000) S, max. Arch degree be in the scope of middle span S/10. 5.There are saddle seat jointed with legs in the two sides of span position, and there are square steel plate connect with flange. 6.Buffers at the girder ends ensure trolley's safe traveling along the main girder |

|

Ground beam

1. Ground beams support the main girder and load, and also connect main girder and traveling mechanism, one of the main loading metal structures. 2. Box structure girder welded by U-type groove and steel plate group or only steel plates, with features of light structure, good rigidity, appearance and welding technology. 3. Buffers settled at the ends of ground beam |

|

Legs

1.Isosceles trapezoid or right or left trapezoid box pillar welded by steel plate. Wide flanges welded at the upside and narrow flanges at the downside of the pillar increase the rigidity and stability of the gantry frame 2.Two flexible legs designed for improve crane traveling effect when span ≥ 30m. 3.Bolts connect two flanges to become an "A" structure, increasing the crane's stability. 4.Bolts connect steel plate flange between legs and ground beam, simple structure, easy to install, transport and store. |

|

Other parts

1.Lifting Mechanism - CD or MD wire rope hoist 2.Crane Traveling Mechanism 3.Drive separately, composed of traveling motor, traveling reducer, wheel group, etc. |

|

Pendant control

Remote control

Cabin control |

Operation

1.Ground control and cabin control 2.The cabin has open style, close style,can fixed on left or right 3.The open direction include end open,side open or top open 4.The cabin includes special small room for single-girder and capsule cabin 5.Ground control has handle and remote control, do not need to set up special driver 6.Users can choose as you need 6.Users can choose as you need |

Overall Organization Drawing

MH single girder gantry crane for construction station

MH single girder gantry crane for cement factory

MH single girder gantry crane for workshop

MH single girder gantry crane ( box type )

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.