1.Variable speed, Soft starter;

2.Wireless Radio Remote control;

3.Shrouded DSL system for power feeding;

4.Flameproof, Cabin Operated;

5.PLC automatic Control system;

6.High quality carbon steel Q345;

7.All electrical appliance adopt china first-class brand, Siemens,Schneider or according to your demands;

1.lt widely apply in port dock and electricity plant etc, loading and unloading coal etc.

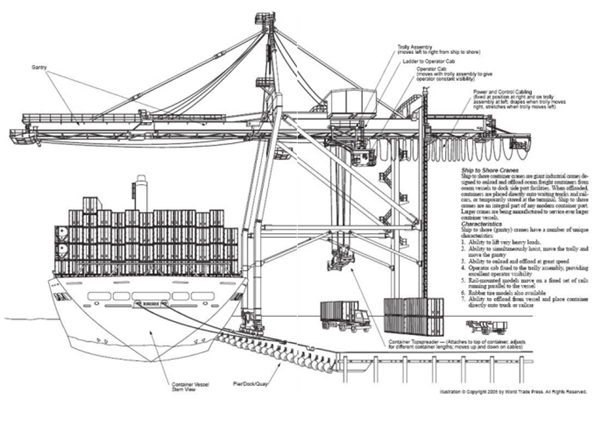

2.lt is composed of bridge, support legs, crane traveling organ, trolley, electric equipment, strong lifting winch, the frame adopts box-type welding mechanism, crane traveling mechanisms are operated in the driver cabin or remote control, Power is supplied by cable or slide wire.

5-10 load/unload container crane mainly composed of steel, lifting structure,tilt mechanism, crane traveling mechanism, trolley traveling mechanism, machine room, lift container spreader, electrical equipment and other necessary safety and auxiliary equipment.

Depending on the type of trolley, the model is divided into traction, semi-traction, self-propelled, with the adoption of PLC control systems and CMMS automatic-fault monitoring and diagnostic functions,there is sufficient communication and lighting. The steel is divided into single, double box structure,the girder structure and H-type gantry structure.

Load capacity : 5tons - 10tons

Load container at port

Can be customized

Excellent quality

|

Rated productivity (t/h) |

600~2500 |

|

Capacity (t) |

16,32,55 |

|

Hoisting Speed (m) |

Above 18~24 / Below12~33 |

|

Material specific gravity (t/m³) |

0.9~3.0 |

|

Max. front outreach (m) |

20~55 |

|

Rail gauge (m) |

17,30 |

|

Wheel base(m) |

12,17 |

|

Hosting/opening/closing speed(m/min) |

100~150 |

|

Cross Travel speed (m/min) |

120~250 |

|

Luffing time (min) |

5 |

|

Long Travel speed (m/min) |

20 |

|

Max.wheel load(KN) |

200 |

|

Power |

10kv,50Hz,3ph |

1.Overload protection;

2.Main lifting motor with thermal protection;

3.Hooks with latch;

4.Rubber buffers;

5.Protective earthing;

6.Crane switch and travel end switch;

7.Emergency switch can stop all movement when dangerous happened;

8.Sub-assemblies characteristic are tested before assembly;

9.All cranes must be assembled and tested before leaving factory and offer the certification of test

a) Electric parts are packed by high quality wooden box, to reduce distortion in conveying.

b) Main beams, ground beams are packed by plastic woven cloth. It can reduce abrasion when transport.

Warranty

We'll be responsible for maintenance if our product itself has quality problem during one year after receiving.

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.